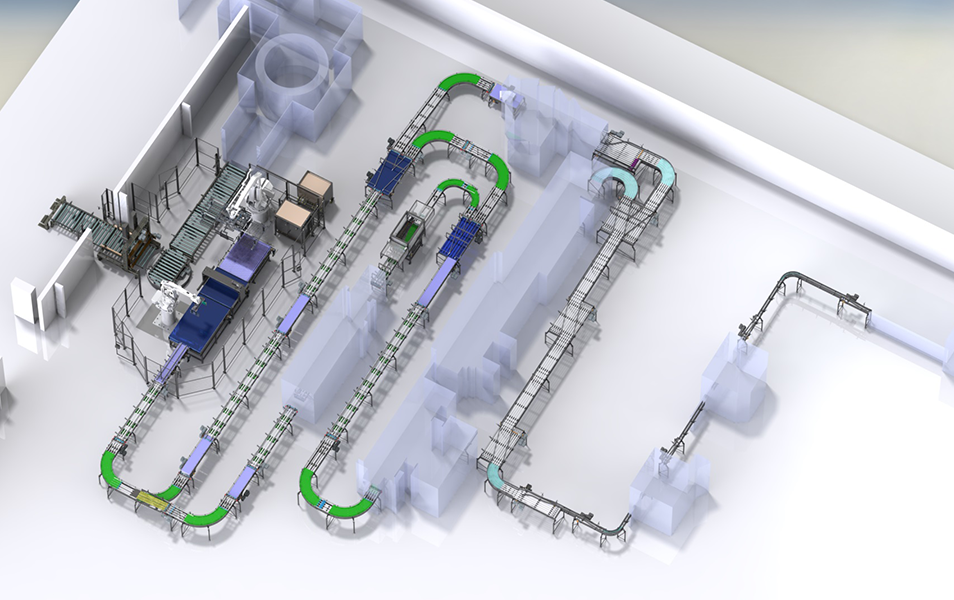

Our first years were dedicated to creating project and engineering solutions for industrial intralogistics systems, mostly for the food industry.

Proven experience and market visibility were clear from the first year of Pentaline®, where the company started to develop highly specialized engineering projects, leading to a solid, sustained growth and synergies with other companies.

This growth strategy resulted in the clear exponential growth of Pentaline®. The company was able to consolidate its market presence, strengthen relationships with key customers, accomplish new business opportunities, and partner up with relevant equipment suppliers in the market.

2004

Pentaline® was founded by the managing partners João Almeida and Lurdes Valquaresma

Given the renowned technical ability of the founder, a huge job was awarded to the company by a prestigious customer in the first year of activity: the integration of the whole production capacity of group Sumol (Lisbon, Viseu, and Pombal) in the production centre of Pombal

2005

Pentaline® internationalization

Standard Pentaline® machinery exported to plants:

2006

First robotic islands installed

Delivery of two end-of-line palletizers for:

2007

Pentaline® internationalization was reinforced

Engineering of lines w/ the supply of standard Pentaline® machinery and conveyors for the plants:

2007

Won a leadership award

Pentaline wins the first Leader SME, which has been won ever since.

2008

Leader in industrial robotics

Integration of four end-of-line palletizers for major national groups:

2008

Entry into the national market of continuous washers

In the following years, these represented a significant share of exports.

First rinser installed at Victor Guedes.

2009

Águas de Penacova gets its production lines optimized by Pentaline®

Line engineering job that resulted in the increase of filling speed and capacity from 2.500 to 5.500 large bottles/hour and from 9.000 to 22.000 regular bottles/hour.

2009

First high-speed rinser installed

Double rinser (2 x 50.000 bottles/hour) integrated for the cleaning of glass bottles at Super Bock Group. Machine subject to the strictest quality control for acceptance.

2010

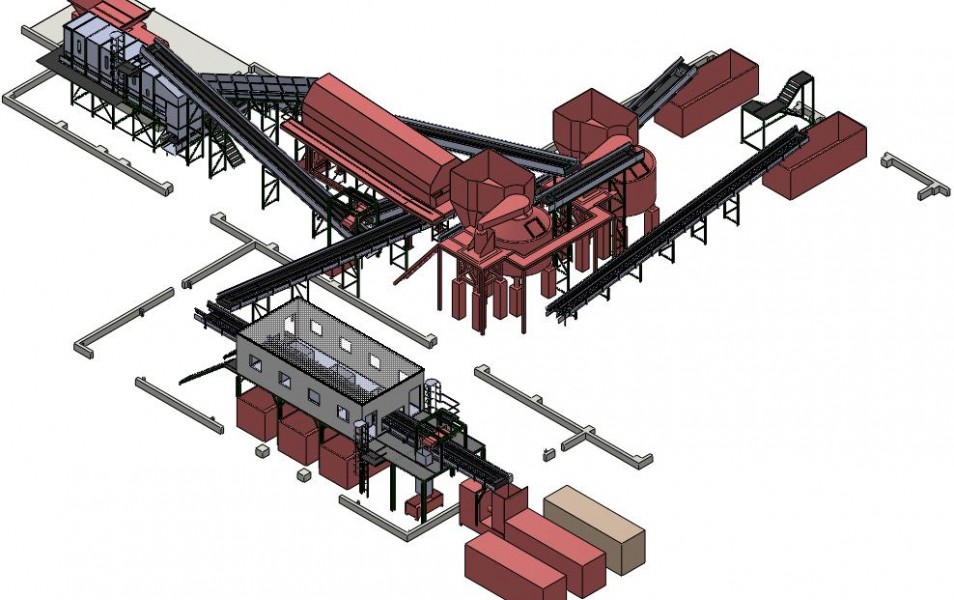

Entry into new markets

Engineering, manufacture, and assembly of full lines for the treatment of urban waste.

2010

Pentaline® internationalization was reinforced

Stadard Pentaline® machinery exported to plants:

2011

Pentaline® rebranding

The second Pentaline® logo was developed to emphasize and renew company’s image in the market.

2012

Pentaline® robotics was reinforced

Delivery of five end-of-line palletizers for:

2013

Moved to other facilities

Equipment assembly and acceptance testing indoors.

2013

Optimization of production process via tailored R&D study

Development of an innovative cheese conveying, palletizing, depalletizing, and robotic handling process at group Fromageries Bel.

2014

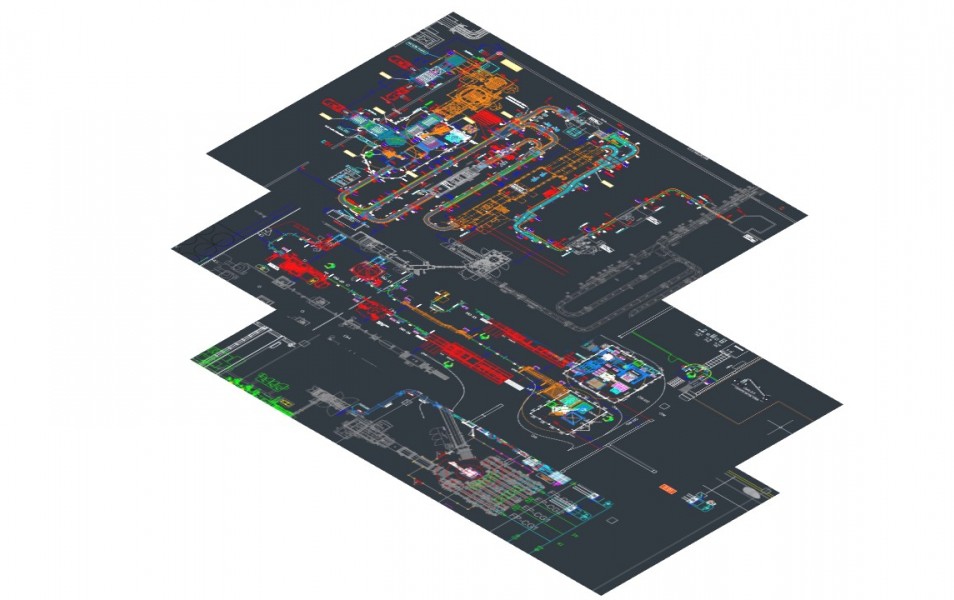

Internal management software was reinforced

Implementation of a new management system at Pentaline®. With the integration of all resources and a base for permanent scalability, the PHC allowed for an exponential growth.

2014

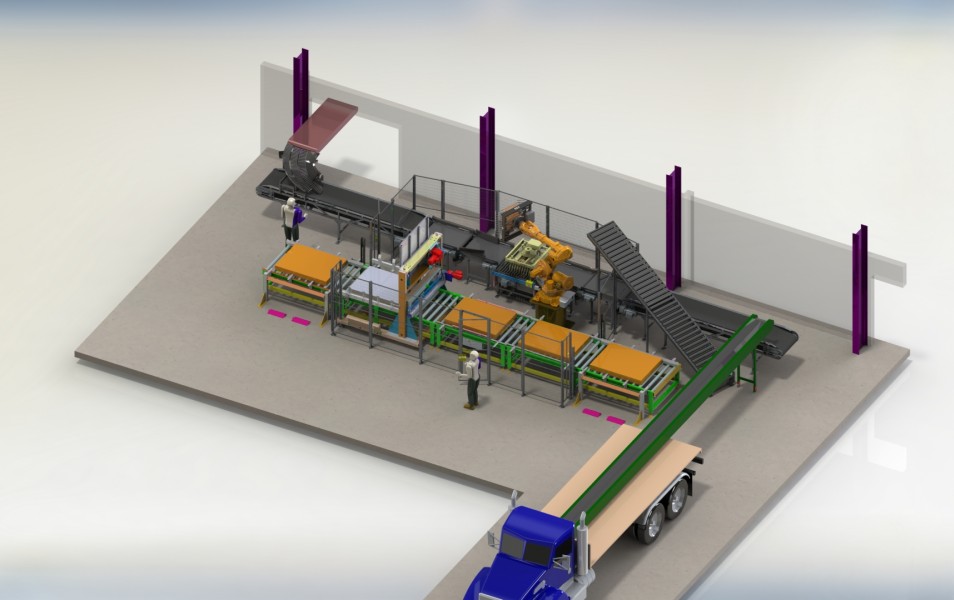

Entry into new markets

Pentaline® wins the first large-scale job in the Tissue sector for renowned international competitors and in the coffee sector w/ a full end-of-line palletizer for bags.

2015

Operation area expanded

Pentaline® was chosen for the supply of a full line of canned food. From can reception, conveyance of multiple types of packing, and robotic palletizing.

2016

Pentaline® rebranding

The third Pentaline® logo was developed to make company’s identity more mature and reflect its renowned technical ability and presence in the international market.

2017

New Pentaline® facilities were prepared

Beginning of the construction of a new, resized plant that suits the technological evolution and growth of the company.

2017

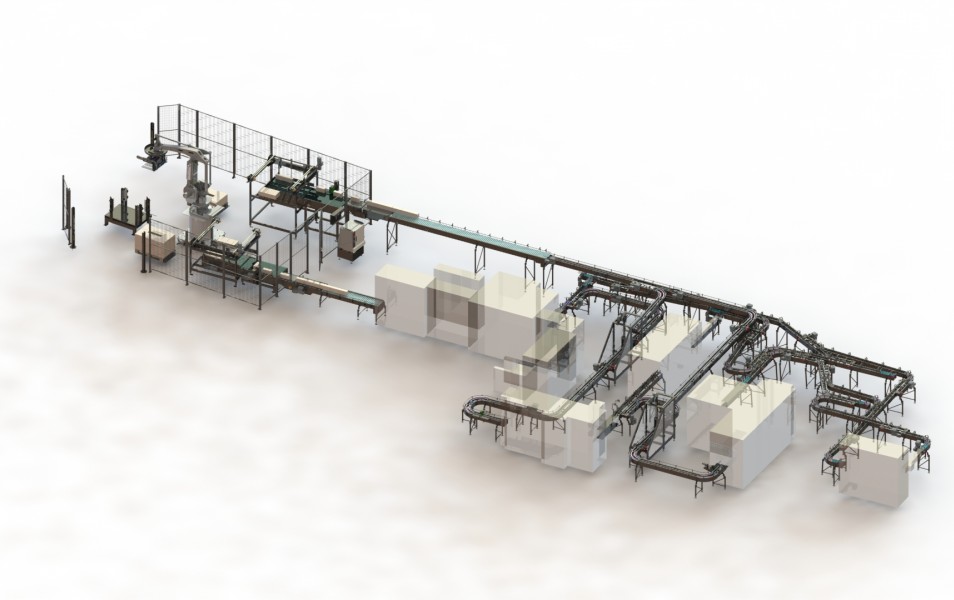

International presence was reinforced with a full high-speed line

Pentaline® wins international competition w/ full water line (bottles, packs, boxes, pallets conveyors and robotic, flexible end-of-line palletizer) in Spain. Presence in the European market was reinforced w/ a reference of strength and technical capacity.

2018

Reference year for the cross-sectional improvement of Pentaline®

2019

Marketing standards and initiatives reinforced for continuous improvement

2020

Articulation between production processes and marketing initiatives improved

2004

2005

2006

2007

2007

2008

2008

2009

2009

2010

2010

2011

2012

2013

2013

2014

2014

2015

2016

2017

2017

2018

2019

2020

• Long-term, consolidated strategies;

• Organic and sustained growth;

• Innovative solutions;

• Full satisfaction of customers’ requirements;

• Customized, permanent customer follow-up;