VACUUM, CLAMPING OR MAGNETIZING OPTIONS

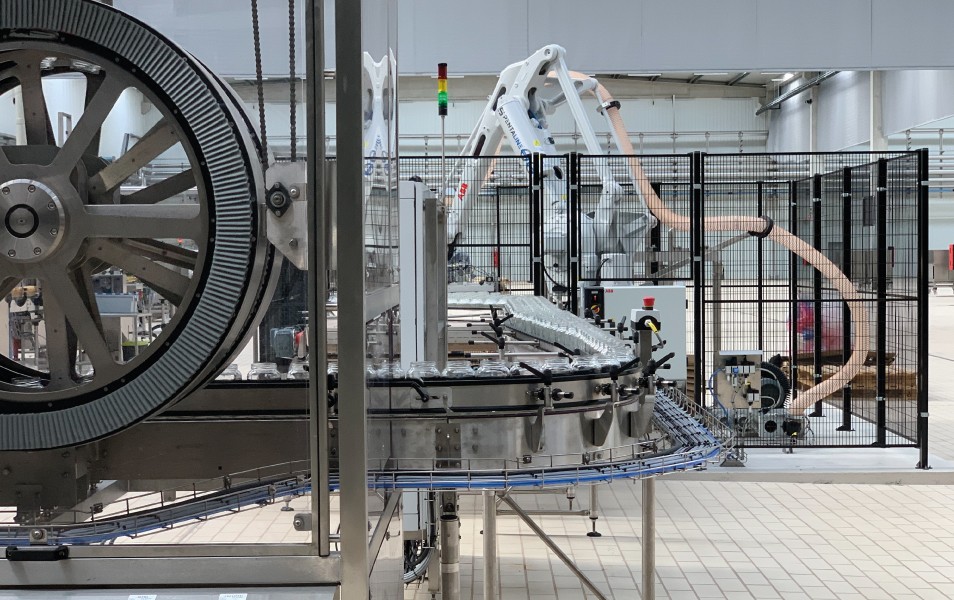

Depalletizing robotic system designed to handle products layer-by-layer, by vacuum, clamping or magnetization. Basic solution with layer depalletizer. This model has several available options for increased cadence, where operations are segmented through more robots or peripherals.

- Modular concept allows adding multiple other features, e.g., a 2nd robot dedicated to slip sheet handling and various product input and output stations, others upon request;

- Automatic and instant format changeover, without mechanical adjustments;

- Floor-level depalletizer facilitates access and maintenance;

- Customized solution adaptable to existing layout;

- Possibility of one or several pick-and-place robot stations;

- Equipment designed to allow every layer dimension

- Mechanical design and user-friendly interface guarantee a quick commissioning and easy maintenance in the future;

- Models designed with a focus on efficiency, robustness, simplicity, and space optimization;

- Compact versions are suitable for handling a wide range of products, but can be scaled up in size when features are added to increase productivity or versatility;

- Multi-track table to accommodate complete product layer and pneumatic ruler to avoid jams. Orthogonal conveyors or pressureless aligners can be considered to increase productivity;

- Robust pneumatic grippers with suitable construction/contacts to the product being handled and according to available space (vacuum or clamp);

- Layer gripper with vacuum management with the possibility of reversing the flow to clean the channels;

- Gripper with squeezing device that can be combined with a vacuum system to depalletize different types of layers and mix them on a new pallet;

The areas of application and products to be handled are diverse:

- Food, beverage, pharmaceutical, and others;

- Packages, boxes, crates, bottles, jars, cans, buckets, and other types of products under confirmation;

- All pallet and slip sheet sizes;

DRAGGING OPTION

Depalletizing robotic system designed to handle products layer-by-layer by dragging. Basic solution with layer depalletizer and centering ring with jaws for slip sheet positioning. This model has several available options for increased cadence, where operations are segmented through more robots or peripherals.

- Modular concept allows adding multiple other features, e.g., a 2nd robot dedicated to slip sheet handling and various product input and output stations, others upon request;

- Automatic and instant format changeover, without mechanical adjustments;

- Depalletize bottles with narrow bottlenecks;

- Floor-level depalletizer facilitates access and maintenance;

- Customized solution adaptable to existing layout;

- Possibility of one or several pick-and-place robot stations;

- Equipment designed to allow every layer dimension;

- Mechanical design and user-friendly interface guarantee a quick commissioning and easy maintenance in the future;

- Models designed with a focus on efficiency, robustness, simplicity, and space optimization;

- Compact versions are suitable for handling a wide range of products, but can be scaled up in size when features are added to increase productivity or versatility;

- Multi-track table to accommodate complete product layer with a pneumatic ruler to avoid jams. Orthogonal conveyors or pressureless aligners can be considered to increase productivity;

- Robust pneumatic or servo-controlled grippers with suitable construction/contacts to the product being handled and according to available space (dragging);

- Centering ring to handle layers and jaws to hold slip sheets;

- Food, beverage, pharmaceutical, and others;

- Bottles, jars, cans, buckets, and other types of products under confirmation;

- All pallet and slip sheet sizes;